On this page

- Water treatment and source control in the Elk Valley

- EVR’s treatment timeline

- Source control techniques

- Water treatment

Water treatment and source control in the Elk Valley

Mine planning and design are important first steps in preventing or limiting the release of mining-related substances into the environment. This is known as ‘source control.’

Efforts are also made to keep water clean by diverting it away from areas (such as, waste rock) that may worsen water quality.

Water treatment is used to remove substances from the water that cannot be avoided by source control practices.

The Elk Valley Water Quality Plan and Permit 107517 require EVR to develop and implement strategies for both source control and water treatment. EVR is operating new treatment technologies to remove selenium and other substances from mining-impacted water. Based on modelling predictions, more water treatment facilities are needed in the Elk Valley until at least 2042.

The B.C. government regulates all activities and infrastructure on mine sites, including treatment facilities. Everything must be approved in permits. The permitting process is a robust and sometimes multi-year process. It includes a detailed review of engineering and assessments by qualified professionals. This work ensures treatment facilities, as well as other infrastructure and activities, are safe and effective when operating.

EVR’s treatment timeline

Timeline

2014

• The Elk Valley Water Quality Plan is approved by the B.C. Minister of Environment

• Permit 107517 is issued to establish water quality limits and define treatment requirements

2015

• First selenium and nitrate Active Water Treatment Facility (AWTF) begins treating water at Line Creek Operations mine

2017

• First calcite treatment facility begins operating at Greenhills Operations mine

2018

• B.C. government approves a pilot Saturated Rock Fill (SRF) treatment facility for selenium and nitrate at Elkview Operations mine to test this new technology

• More treatment added to the AWTF at Line Creek Operations to prevent calcite formation and to prevent selenium from changing into more harmful varieties

2020

• The SRF at Elkview Operations is made permanent and expanded to include calcite treatment

2021

• Calcite treatment facility begins operating on Dry Creek at Line Creek Operations

2022

• Fording River Operations South AWTF begins treating for nitrate, selenium and calcite

2023

• North-1 SRF to begin operating at Fording River Operations

2025

• New North Line Creek SRF at Line Creek Operations and expansion of North-1 SRF at Fording River Operations are planned

2026

• Second North SRF planned at Fording River Operations

2027

• New and expanded treatment facilities planned at Greenhills Operations and Elkview Operations

2033 and beyond

• More treatment facilities are proposed at all mines

Source: 2022 Implementation Plan Adjustment

Source control techniques

EVR is implementing new options to control mine waste and reduce treatment needs. For example, improved blasting practices are reducing the release of nitrate.

Other techniques are being investigated and piloted, such as the use of geomembrane covers for waste rock piles and suboxic zones. A geomembrane is a protective layer that can be put on top of a rock pile or other source of mine waste. A suboxic zone is a rock disposal area that’s engineered to keep oxygen away from waste rock. These techniques prevent waste rock from contacting air and water, which reduces the release of selenium and other substances.

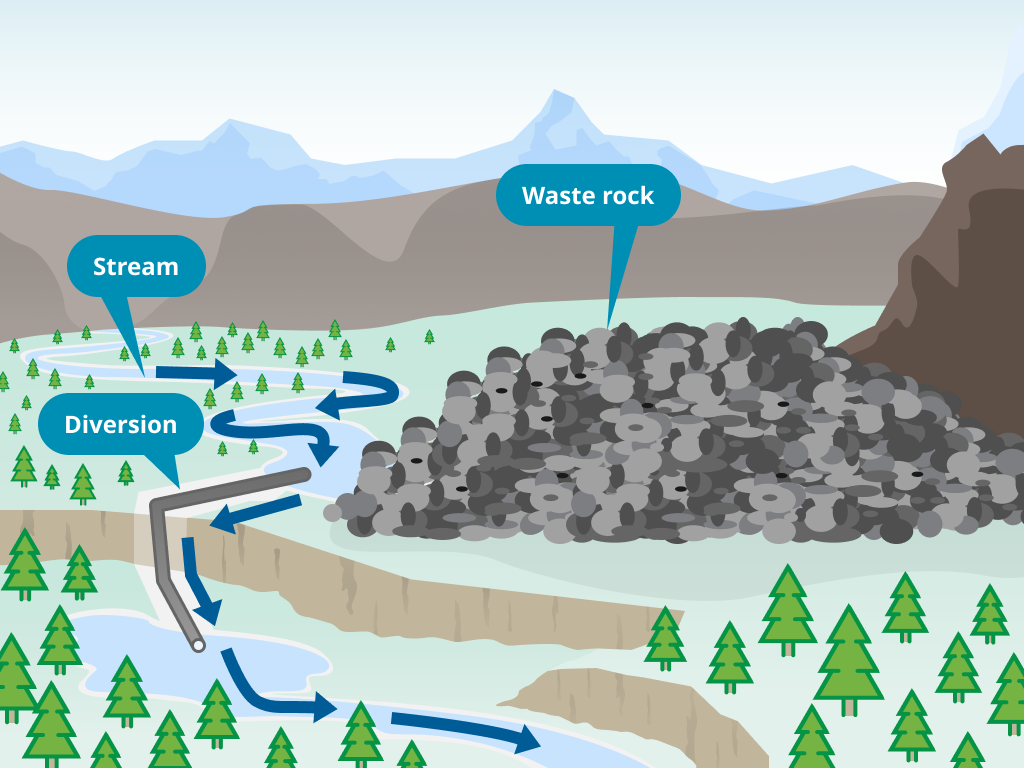

Clean water diversions

Clean water is diverted around waste rock piles to avoid contamination.

Diversions move clean water, such as streams, away from mining areas like waste rock dumps. This helps keep water clean and reduces the amount of water needing treatment.

Waste rock dumps are stockpiles of rock that have been exposed by mining. Diverting water away from these areas stops the water from picking up substances like selenium.

Studies ensure proposed diversions will not negatively affect aquatic ecosystems and are compatible with other water uses. Before diversions can be constructed, they’re approved by the Province.

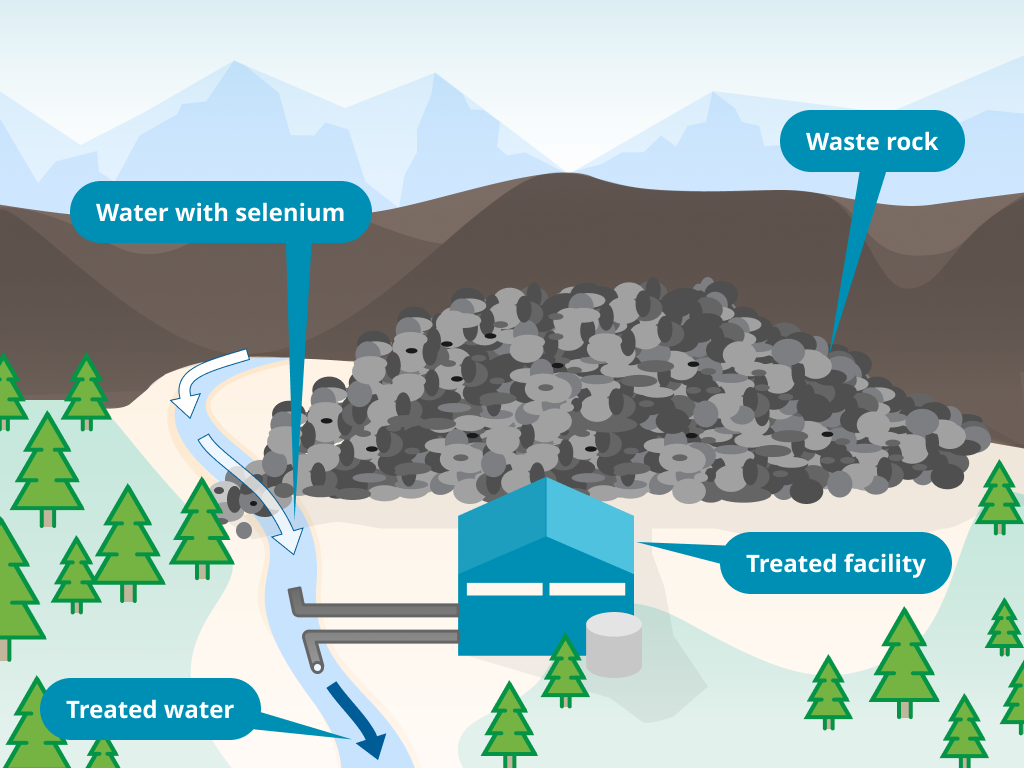

Water treatment

Water treatment collects mining-impacted water from the environment. The water is sent to a treatment facility where substances are removed before the cleaned water is returned to the environment.

Facilities require permits from both the Ministry of Energy, Mines and Low Carbon Innovation and the Ministry of Environment and Climate Change Strategy before they can be used on a mine site.

New treatment technologies must be developed and tested in a lab and then in the field as a small pilot test before they’re permitted at their full size on a mine site.

There are many different types of water treatment. Two methods that have been demonstrated to treat selenium and nitrate at the scope and scale required in the Elk Valley are:

- Active water treatment facilities

- Saturated rock fills

Calcite treatment is also being used in the Elk Valley to prevent deposits on stream bottoms.

EVR is exploring other technologies to treat substances regulated in the permit.

Active water treatment facilities

Active water treatment facilities remove selenium and nitrate from water.

There are many different technologies that can be used in an Active Water Treatment Facility (AWTF). The technology selected depends on what substances need to be removed from the water. EVR’s AWTFs are designed to remove nitrate and selenium. They work by pumping the water through tanks containing bacteria that consume the selenium and nitrate and remove these substances from the water. The removed substances are pressed into a solid and put in a landfill.

EVR’s Initial Implementation Plan for the Elk Valley Water Quality Plan relied solely on this technology and clean water diversions to meet water quality targets. At the time, these were the only options that were ready to be used in the field.

EVR’s first AWTF, the West Line Creek AWTF, began operating in 2015 at the Line Creek Operations mine. Monitoring showed that treatment removed significant amounts of selenium. It also showed that some of the selenium changed into a form that could more easily accumulate in aquatic life. This meant that the lower selenium levels in the downstream water were still resulting in accumulation in plants and animals.

EVR tested technologies and found a chemical treatment process called advanced oxidization, which prevented the selenium from changing form. In 2018, an advanced oxidization process was added to the West Line Creek AWTF.

A second AWTF was developed and is operating at Fording River Operations. This facility is known as the Fording River South AWTF and it also includes an advanced oxidization process.

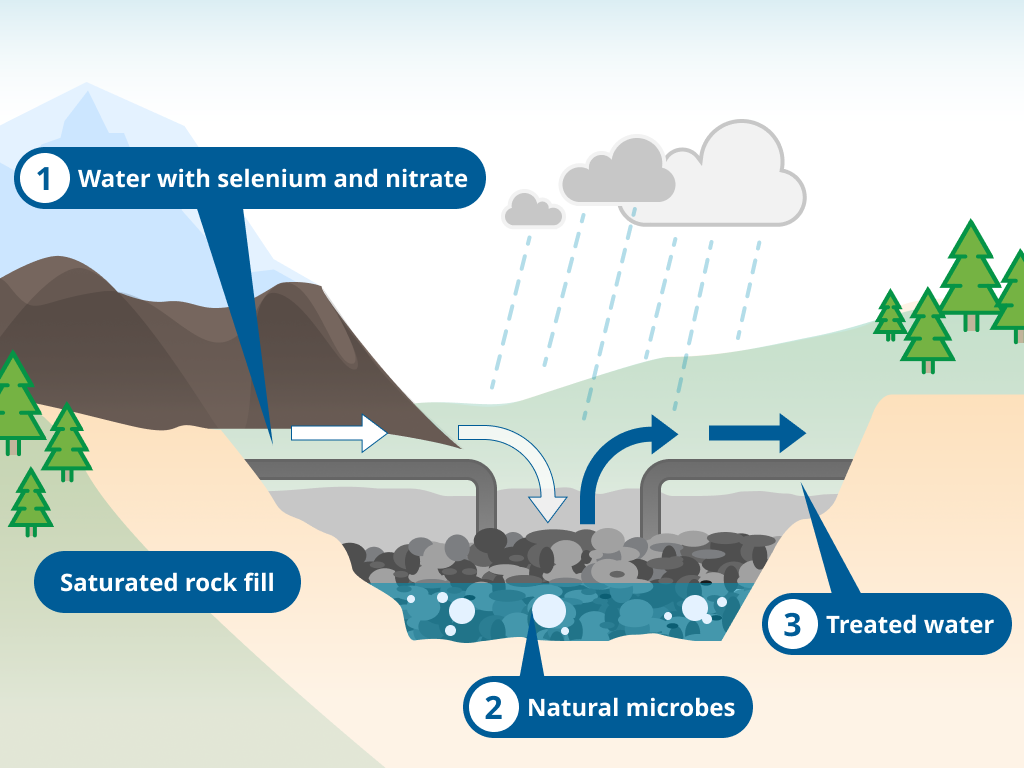

Saturated Rock Fill

Saturated rock fills remove selenium and nitrate from water.

Saturated Rock Fill (SRF) technology is a new treatment method being developed by EVR in the Elk Valley. Like the AWTFs, SRFs also treat selenium and nitrate using bacteria. Research shows this new technology is effective. EVR has determined the SRFs require a much smaller footprint because they use existing mine infrastructure and can be much less costly to build and operate than an AWTF.

The new technology is being integrated into EVR’s planning. A SRF at Elkview Operations mine is operating and a second facility at Fording River Operations is being developed.

Saturated Rock Fills consist of open pits filled with waste rock and saturated with water. Water with high amounts of selenium and nitrate is injected into the saturated waste rock in one part of the pit using wells and pumps. Bacteria consume the nitrate and selenium as the injected water flows through the waste rock. Selenium is turned into a solid form that falls out of the water and remains in the pit and nitrate is converted to a gas which is released harmlessly into the air.

Cleaned water is removed from the SRF through pumping wells. Since selenium solids stay in the pit and nitrate is converted to a gas that’s released into the air, SRFs do not generate material that needs to be landfilled.

Calcite treatment

Greenhills Creek calcite treatment facility.

Calcite treatment facilities are used to prevent formation of calcite on stream bottoms in the Elk Valley.

Calcite is found naturally in rocks in the Rocky Mountains. It can be released through mining into surface and groundwater and may build up downstream. Calcite hardens stream bottoms. This reduces plant growth and degrades habitat for aquatic life.

Antiscalants are compounds used in calcite treatment facilities that stop calcite from building up downstream. Calcite treatment is incorporated into 4 water treatment facilities. Four stand-alone calcite treatment facilities have also been established. These 8 treatment facilities are preventing new calcite deposits.

EVR has identified limited options for removal of calcite once it has built up on stream bottoms. Efforts are focused on using calcite treatment facilities before calcite becomes an issue or to prevent conditions from worsening.